How to take off and climb an aircraft

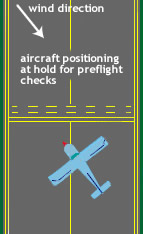

After taxying to the holding point of the runway in use, the aircraft is aligned to about 45° to the runway and towards the wind. Aligning the aircraft in this manner ensure that the prop wash created during the full power tests does not damage an aircraft that may be behind you. The pre-takeoff check list is accomplished. The checks are always enumerated in the pre-flight check list which should always be available in the cockpit. Checks will include engine functions, and fuel. With the brakes full on, the engine is run up to high revs, usually 2200 rpm, and each magneto is cut in turn. This will result in an RPM drop which should normally not exceed 125 RPM. The carb heat is tested, which should show a small drop in RPM. If the aircraft is complex, the propeller is recycled twice by increasing pitch sufficiently to reduce the RPM by at least 100. The engine RPMs are then dropped to tick-over to ensure that even running is experienced. The fuel boost pump is switched on and if the airfield is controlled, permission to line up is requested.

First degree of flap is usually applied, and the elevator trim adjusted to neutral. When this is completed, and clearance is given, the airplane is taxied to the centre of the runway and aligned with it. The throttle is opened fully to start the takeoff run (also called take off roll). During this takeoff run, the control wheel, or stick, is usually held in the neutral position, but the rudder pedals are used to keep the airplane on the runway's centreline. If the aircraft has a castoring nosewheel, small dabs of differential brake will be required until sufficient airspeed has been attained to give rudder authority.

The sudden increase in engine power will place and uneven pressure on the empennage. This will result in a tendency to yaw, which must be counteracted using the rudder pedals. Some aircraft offset the engine installation to reduce the effect. Most engines rotate clockwise, which will produce a yaw to the left and require right rudder. Anticlockwise engines (some older British types for instance) will produce the opposite effect. A large power decrease will cause the aircraft to yaw in the opposite direction.

If a crosswind is present, the control wheel is held towards the wind to prevent the windward wing lifting.

As takeoff airspeed is approached, gentle back pressure on the control wheel raises the elevator which causes the airplane's nose to pitch upward slightly. This lifts the nose wheel off the runway

(see fig. below).

Once the nose wheel is off the runway, the more right rudder will probably have to be applied to counteract the left-turning tendency which is greater once the aircraft leaves the ground. As the airplane lifts clear of the runway, the pilot varies the pressure on the control wheel. First, pressure is relaxed slightly to gain airspeed while still in ground effect (additional lift provided by compression of air between the airplane's wings and the ground). As airspeed increases to the best rate-of-climb airspeed, back pressure on the control wheel is adjusted to maintain that airspeed until the first desired altitude is reached. (Best rate-of-climb airspeed provides the most altitude for a given unit of time.) Once the runway is clear, the undercarriage is retracted (if the aircraft is complex) and flaps are returned to neutral (clean) at about 300 feet.